Workshop Technology

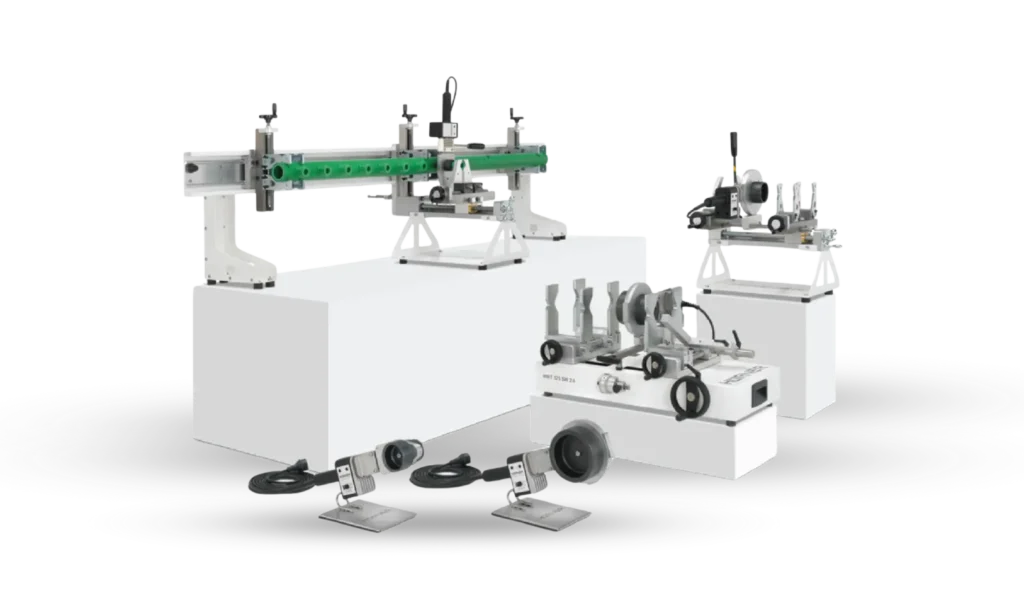

HÜRNER HWT 160 CS and 400 Line

HWT 160 CS and HWT 400 bring full worksite welding to the workshop for making segments, tees, Ys, and crosses from PVC, PE, PP, and PVDF pipes O.D. 32–400 mm. CNC, WeldControl, and manual versions feature heavy-duty frames, memory for 10,000 reports, USB export, DataWork, label printing, sidewall fusion, and one-sided preheating.

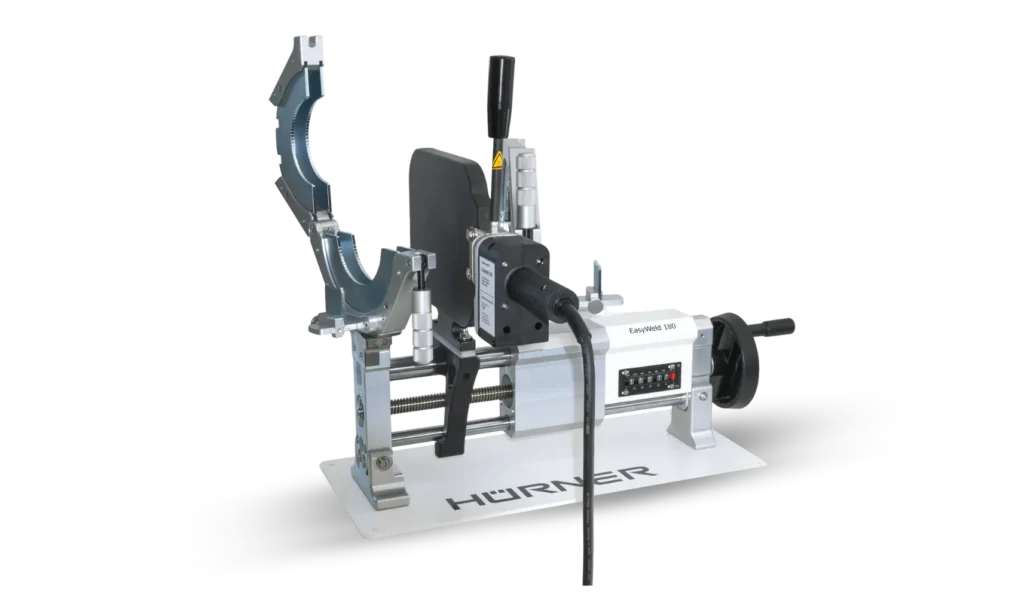

HÜRNER EasyWeld Line

HÜRNER EasyWeld Line butt-welds PE, PP, PVDF pipes and fittings O.D. 20–110 mm & 50–180 mm for all pressure classes. Compact, lightweight, and mobile for worksites or workshops, it has adjustable clamps for tees and bends, a heavy-duty base, ergonomic tools, and an electronically controlled PTFE-coated heater for precise, high-quality joints.

HÜRNER HWT-160 M

Versatile butt-welding machine for PE, PP, and PVDF pipes O.D. 40–160 mm (1½”–6″), ideal for on-site or workshop use. Suited for sanitary, drain, water lines, and refurbishments, it’s plug-and-play with stand, facing tool, heater, and inserts. Swiveling clamps (±15°) weld bends, and the removable heater fits HÜRNER’s support stand.

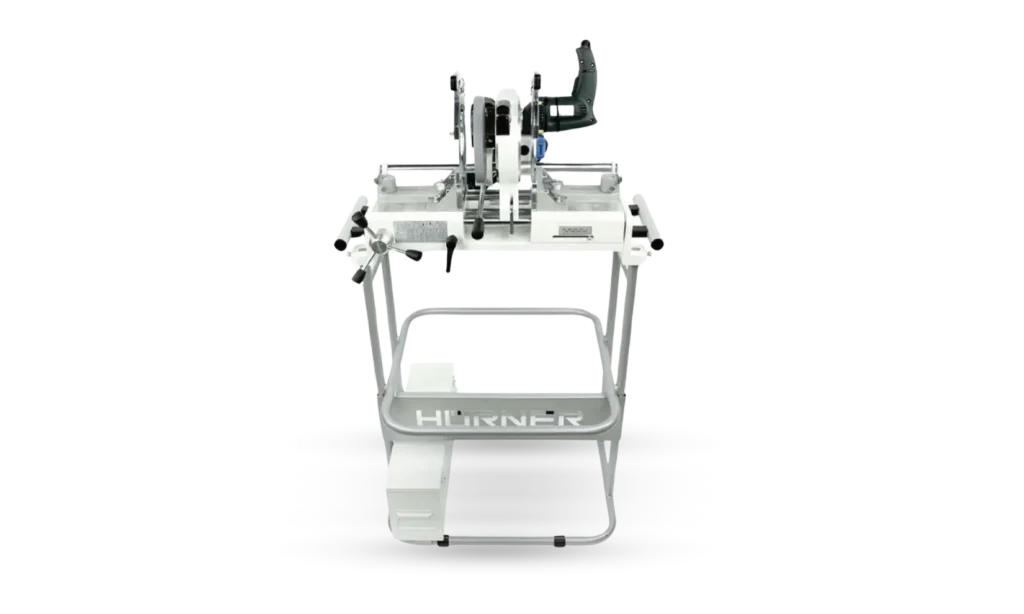

HÜRNER HWT SW Line

HWT 160 SW-S, SW-E, 125 SW 2.0, and 125 SW Light socket welders join PP, PP-R, and PEHD pipes, making branch-offs O.D. 20–90 mm from mains O.D. 40–160 mm. Ideal for tight spaces or serial production, they have quick-change clamps, ergonomic handwheels, drill compatibility, precision aligners, and adjustable heaters for fast, consistent welds.